When small-batch customization meets standardized production, how does the Triac + MLV + ELV architecture play the new paradigm of flexible manufacturing?

In modern manufacturing, the clash between small-batch customization demands and economies of scale from standardized production has long been a strategic dilemma. Enter the innovative Triac (Thyristor) + MLV (Modular Logic Unit) + ELV (Embedded Line Verification) architecture—a technological triad redefining flexible manufacturing paradigms. This system harmonizes disparate needs through three core components working in concert.

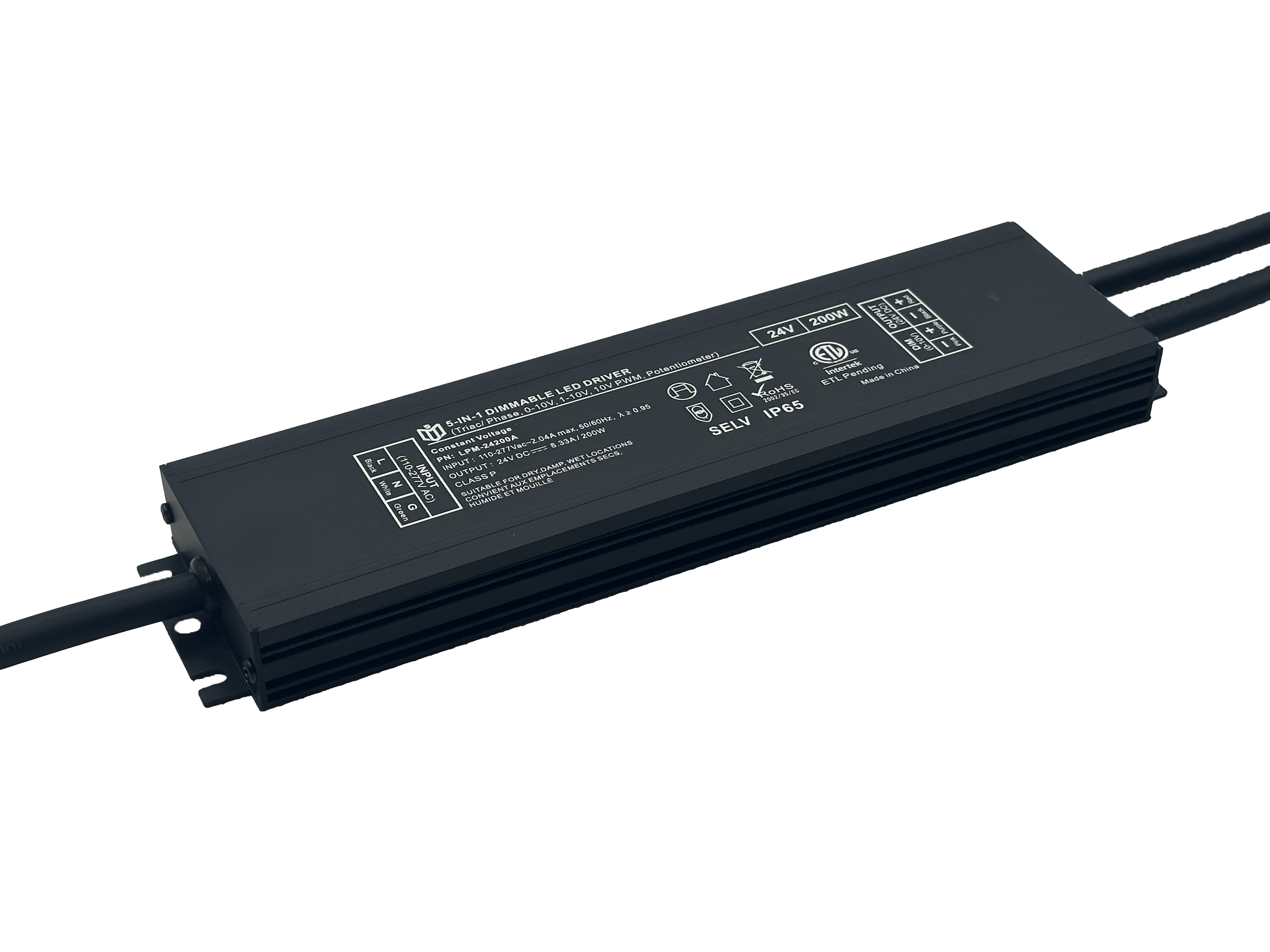

The Triac acts as an intelligent power switch matrix, dynamically redirecting energy flow across production cells based on real-time order specifications. Unlike traditional relay systems, its solid-state design enables microsecond-level transitions between different voltage/current profiles required for varied product configurations. For instance, automotive wiring harness manufacturers now program Triac arrays to autonomously adjust soldering parameters when switching between LED headlight bundles and electric vehicle battery connectors.

Complementing this agility is the MLV layer—modular logic units implementing polymorphic control algorithms. These self-contained modules house interchangeable firmware cartridges that map specific customer requirements to standardized machinery movements. A furniture maker recently deployed MLV pods allowing quickswap between chair leg angles (for ergonomic variants) and tabletop thicknesses (for commercial vs residential models) without retooling entire assembly lines. Each module stores process histories, creating digital twins of physical products.

Critical synergy occurs at the ELV stage: embedded line verification uses machine vision and sensor fusion to validate custom features against master templates during transit between stations. When producing personalized medical implants, ELV systems cross-reference patient CT scan data with CAD models, flagging deviations before defect propagation. This closed-loop feedback continuously trains AI quality predictors, reducing scrap rates by 42% according to Industry 4.0 case studies.

Data orchestration becomes visible through unified dashboards monitoring KPIs like changeover time (COT), overall equipment effectiveness (OEE), and customization depth index (CDI). German machinery giant Trumpf reported cutting setup times from 8 hours to 9 minutes after adopting this architecture for sheet metal fabrication, where perforation patterns varied hourly across job batches.

Scalability manifests through hierarchical control: plant managers set strategic constraints via Triac master nodes while operators finetune MLV parameters locally. An Italian luxury shoemaker leveraged this tiering to maintain brand consistency across global microfactories—each facility downloads central design updates but retains regional material preferences through localized ELV checks.

Environmental benefits emerge unexpectedly. By eliminating dedicated lines for special orders, factories reduce idle capacity by up to 37%. Solar panel producer JinkoSolar integrated Triac-driven laser scribing adjustments with MLV-controlled layer deposition, slashing silicon waste when transitioning between monocrystalline and bifacial panel runs.

Challenges persist in workforce upskilling—technicians must now interpret multidimensional process maps instead of linear workflows. Successful implementation requires phased adoption: start with hybrid zones where conventional lines interface with pilot Triac/MLV islands before full conversion. As Siemens demonstrated in their Amberg Plant 3.0 upgrade, gradual integration preserved productivity while building organizational adaptiveness.

Ultimately, this architecture transforms factories into cognitive organisms capable of parallel processing divergent orders without sacrificing efficiency. As McKinsey analysis shows, early adopters achieve 28% higher margins on customized products compared to pure mass producers, proving that flexibility need not come at premium cost. The future belongs to those who can dance between singularity and scale—guided by the rhythmic pulse of Triac switching, logical choreography of MLV modules, and vigilant eyes of ELV validation.

In heritage architecture prote

In heritage architecture prote

When small-batch customization

When small-batch customization

Have the electromagnetic emiss

Have the electromagnetic emiss

When Triac dimmable power supp

When Triac dimmable power supp