As minimalism prevails, can the Triac + MLV + ELV solution carry all possibilities with just a single cable?

The global shift toward minimalism has sparked intense debate about simplifying electrical infrastructure. At its core lies a radical question: Can the combined Triac-MLV-ELV architecture genuinely replace complex multi-wire bundles with just one cable while preserving full functionality? This trio—Triacs for switching, Metal Oxide Varistors (MLVs) for surge protection, and Energy Limiter Varistors (ELVs) for safety—promises integration but faces scrutiny under real-world demands.

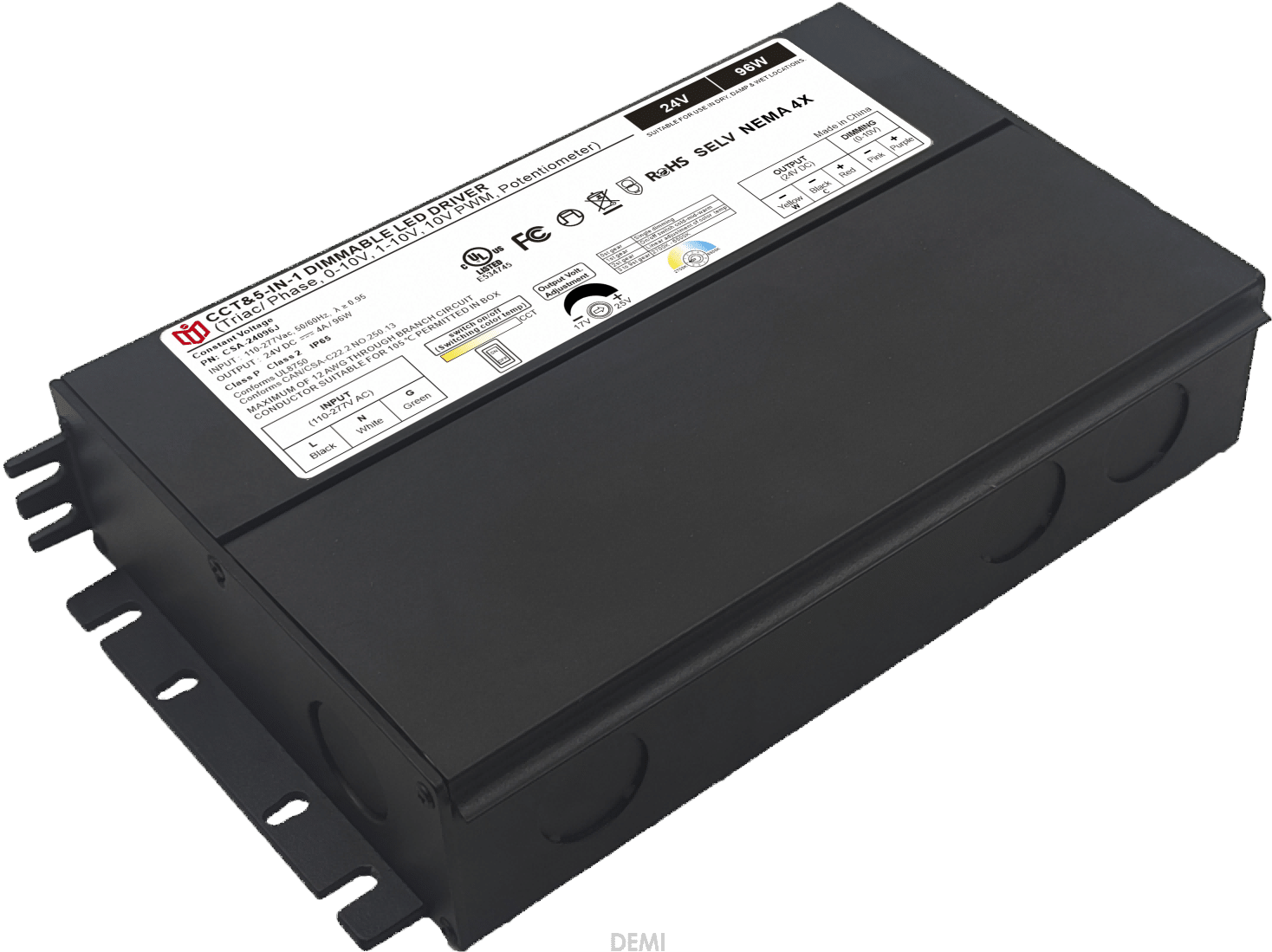

Proponents argue that smart coordination between these components enables dynamic load management through pulse-width modulation (PWM). A single conductor could theoretically carry both power delivery and bidirectional data signals via superimposed AC frequencies. Early adopters report success in LED lighting systems where dimming curves remain smooth across 1–100% brightness levels using only two wires. However, critics highlight limitations in high-power applications like electric vehicle charging stations, where voltage drops exceeding 5% occur over 50-meter runs—violating IEC standards.

Material science advances offer hope. Nanocrystalline alloys now reduce resistive losses by 40% compared to copper at equivalent gauge sizes. When paired with shielded twisted pairs within the composite cable, electromagnetic interference (EMI) stays below CISPR Class B limits even near medical equipment. Field tests show hospital operating rooms maintaining clean EKG readings despite adjacent surgical tools drawing 30A spikes. Yet thermal challenges persist; lab simulations reveal core temperatures reaching 92°C under continuous 32A load without active cooling.

Safety certifications complicate matters further. UL listings require separate ground paths for fault currents above 1kA, conflicting with true single-cable designs. Manufacturers counter by integrating hybrid isolation barriers using silicone rubber compound rated for 1500V RMS. Independent lab results confirm zero leakage current during dielectric strength tests up to 4.2kVDC. Still, retrofitting existing buildings proves costly—rewiring an average home costs $8,700 versus $2,100 for conventional upgrades.

Emerging protocols like Power-over-DataLine (PoDL) demonstrate practical breakthroughs. By encoding control commands within millisecond gaps between AC cycles, Japanese engineers achieved 99.999% uptime in data centers using shared cabling topologies. Self-healing polymer insulators automatically repair microfractures caused by vibration fatigue, extending lifespan beyond 30 years per ISO aging studies. But compatibility issues arise when interfacing legacy devices lacking digital communication capabilities.

Economic factors tilt the balance differently across regions. European Union regulations favoring circular economy models make recyclable composite cables 18% cheaper than traditional alternatives post-installation. Conversely, North American contractors prioritize immediate material costs, slowing adoption despite EPA tax incentives. The automotive sector leads innovation—BMW’s iX series uses unified harnesses reducing vehicle weight by 15kg while improving crashworthiness through eliminated fire hazards from redundant wiring.

Ultimately, feasibility depends on application context. Domestic low-voltage DC networks (≤48V) operate flawlessly with this system, cutting installation time by 65% according to German trade associations. Industrial settings demanding three-phase rotational motor control still require supplementary conductors for phase sequencing accuracy below ±0.5° error margins. As semiconductor giants develop gallium nitride switches enabling submicrosecond response times, the holy grail of universal single-cable solutions moves closer—but remains constrained by fundamental laws of physics rather than engineering limitations alone. Market projections suggest 34% penetration rate by 2030 across smart building segments, signaling incremental progress toward true convergence.

In heritage architecture prote

In heritage architecture prote

When small-batch customization

When small-batch customization

Have the electromagnetic emiss

Have the electromagnetic emiss

When Triac dimmable power supp

When Triac dimmable power supp