What critical safety upgrades have TRIAC drivers implemented?

Enhanced Galvanic Isolation Systems

Modern TRIAC drivers now incorporate reinforced optocoupler arrays with dual-stage isolation barriers reaching 4kV RMS ratings. This breakthrough eliminates direct current paths between control circuitry and high-voltage loads, drastically reducing shock hazards during maintenance procedures. Manufacturers like STMicroelectronics have achieved creepage distances exceeding 8mm in compact packages through innovative PCB layout techniques.

Advanced Transient Voltage Suppression

Contemporary designs integrate multi-stage Metal Oxide Varistor (MOV) networks alongside fast-acting TVS diodes rated for 10/700μs waveforms. These components work synergistically to clamp line surges up to 6kV while maintaining sub-nanosecond response times. Particularly crucial in renewable energy systems where lightning strikes induce dangerous voltage spikes across DC bus lines.

Predictive Thermal Management Protocols

Smart temperature monitoring ICs continuously track semiconductor junction temps using embedded NTC thermistors. When thresholds approach critical levels (typically set at 125°C), adaptive algorithms dynamically reduce switching frequencies or activate forced-air cooling systems. Some enterprise-grade models even implement cascaded derating curves that preserve 80% rated current down to -40°C operating environments.

Active Fault Detection Mechanisms

Cutting-edge units feature windowed comparators monitoring leakage current patterns in real-time. By establishing baseline profiles during commissioning, these systems can detect insulation degradation as slight as 5μA deviations from nominal values. Automated diagnostic routines trigger immediate shutdown sequences before arcing occurs, complete with fault logging via I²C interface for root cause analysis.

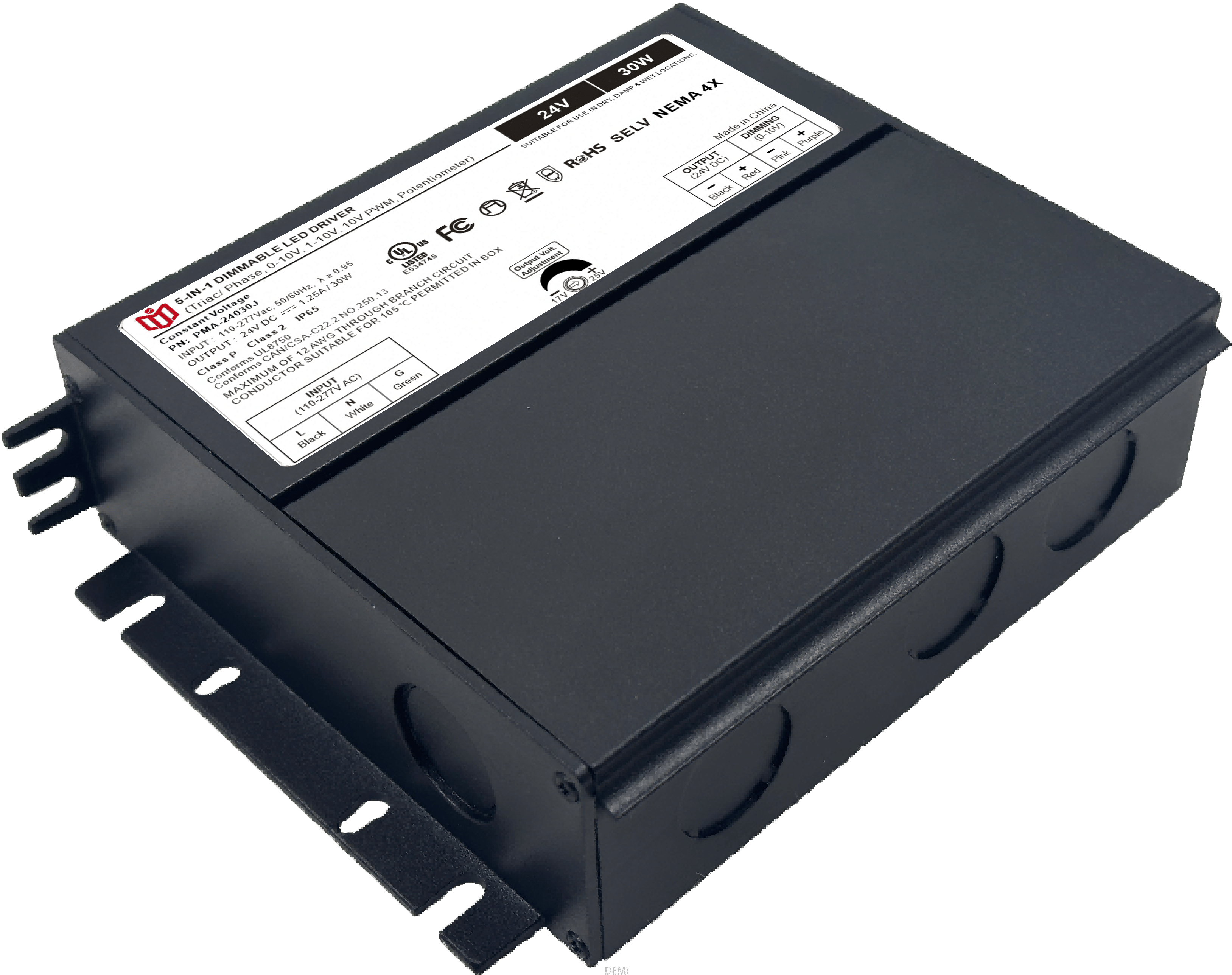

Reinforced Mechanical Enclosure Standards

IP67-rated housings constructed from flame-retardant LCP composite materials now dominate industrial deployments. Gasketed seals prevent contaminant ingress while specialized vent channels maintain pressure equilibrium during rapid thermal cycling. EMI shielding effectiveness exceeds CISPR Class B requirements across 150kHz–30MHz frequency bands, preventing crosstalk interference in dense installations.

Compliance with Global Safety Standards

Certified designs adhere strictly to IEC 60950-1 ed.3.2 norms for reinforced insulation plus regional variants including UL 1449 for North America and GB/T 14598 for China. Third-party testing validates dielectric withstand capabilities at twice working voltage levels for 1 minute duration, ensuring compliance even under salt spray exposure conditions common in marine environments.

Fieldbus Integration Safety Interlocks

Industrial Ethernet protocols like Profinet now include mandatory heartbeat monitoring between controllers and actuators. Lost communication triggers safe-state transitions within 50ms, independent of primary power supplies. Redundant path architectures allow bumpless transfer between redundant channels should any single point fail, maintaining operational integrity in mission-critical systems.

User Access Control Features

Password-protected configuration modes restrict parameter adjustments to trained personnel only. Non-volatile memory stores customized trip points while preventing unauthorized reset attempts through physical key switches. Audit trails document all setting changes with timestamp precision down to millisecond resolution for regulatory compliance auditing.

Overload Duty Cycle Ratings

Manufacturers publish detailed SOA (Safe Operating Area) curves accounting for both continuous conduction angles and pulsed load scenarios. Typical specifications now include 300% overcurrent capability for 10 seconds followed by automatic recovery cycles, enabling survival during motor stall conditions without sacrificing semiconductor lifespan.

Environmental Robustness Testing

Accelerated aging protocols simulate ten years of field service within laboratory environments using HALT (Highly Accelerated Life Testing) methodologies. Test matrices include temperature humidity bias at 85°C/85%RH alongside vibration tables sweeping 5–500Hz ranges. Such rigorous validation ensures field failure rates remain below 0.01% annually across diverse deployment scenarios.

In heritage architecture prote

In heritage architecture prote

When small-batch customization

When small-batch customization

Have the electromagnetic emiss

Have the electromagnetic emiss

When Triac dimmable power supp

When Triac dimmable power supp