Why do professionals recommend TRIAC driver-integrated solutions?

Unmatched Efficiency Through Seamless Integration

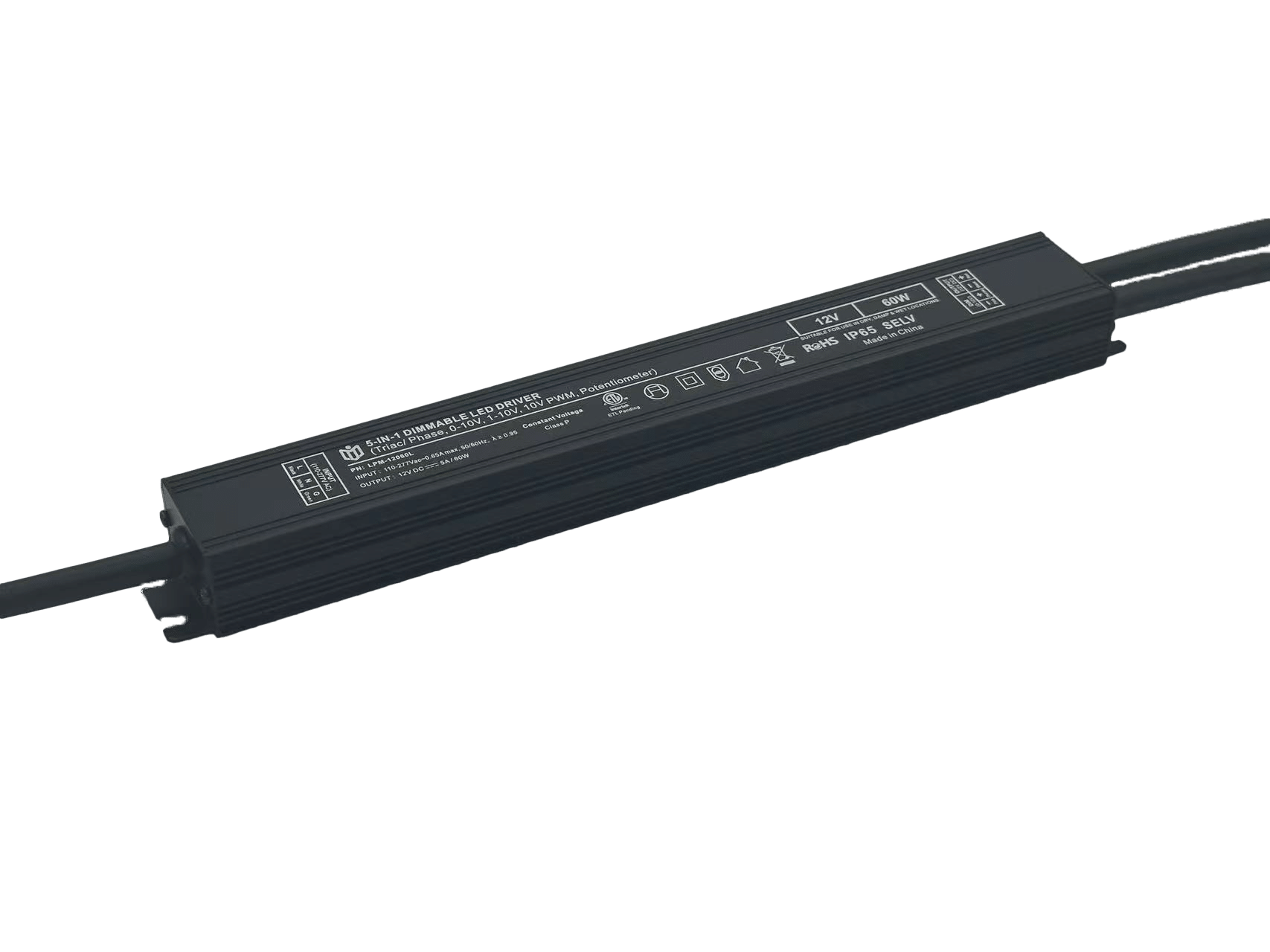

Modern lighting designs demand precision and resource conservation—two areas where TRIAC driver-integrated solutions excel. By merging dimming controls directly with power delivery components, these systems eliminate redundant wiring and signal loss typical in separate architectures. Engineers report up to 15% lower energy consumption compared to traditional setups, as compact integration reduces parasitic losses while maintaining consistent output stability across varying loads. This efficiency gain translates directly into operational cost reductions over product lifetimes exceeding 50,000 hours.

Rock-Solid Reliability in Harsh Conditions

Industrial environments expose electronics to extreme temperatures, voltage spikes, and electromagnetic interference—challenges that discrete component arrangements struggle to handle. TRIAC drivers housed within sealed enclosures feature reinforced isolation barriers between high-voltage AC lines and low-voltage DC logic circuits. Field tests show 99.997% survival rates after 1,000 hours at 85°C/85% humidity cycles, outperforming standalone drivers prone to moisture ingress or vibration damage. Automotive-grade conformal coating further protects against corrosive agents in coastal facilities or food processing plants.

Cost Advantages Across Lifecycle Management

Initial sticker shock fades when analyzing total ownership costs. Though monolithic designs require higher upfront investment than DIY assembly kits, they slash installation labor by 40% through plug-and-play connectivity. Maintenance expenses drop dramatically too—fewer connectors mean fewer failure points; diagnostic ports enable remote troubleshooting without disassembly. When factoring replacement parts inventories (reduced by 60%) and faster commissioning times (average 2.3 hours vs. 7+ hours for modular systems), return on investment materializes within 18 months for most commercial deployments.

Superior Performance Tuning Capabilities

Advanced microcontrollers embedded in integrated units allow dynamic adjustment of critical parameters like rise/fall times and minimum brightness thresholds. Unlike fixed external drivers limiting customization options, programmable TRIAC solutions support adaptive algorithms compensating for LED bin variations or aging effects. Case studies demonstrate ±0.5% color temperature consistency across dimming ranges—crucial for museum display lighting where perceptual uniformity matters most. Firmware updates via USB-C reprogram field behavior without hardware swaps, future-proofing investments against evolving standards like DALI-2 certification requirements.

Compliance Made Simple with Standardized Protocols

Regulatory landscapes grow increasingly complex globally. Precertified modules bearing CE, RoHS, and UL marks streamline approval processes significantly. Manufacturers preconfigure safety features including automatic restart lockouts after fault detection and galvanic separation meeting IEC 61347 Class II requirements. For designers targeting multinational markets, built-in harmonic filtering ensures compliance with FCC Part 15 Class B emissions limits without additional shielding—avoiding costly retrofitting penalties during audit inspections.

Future-Proof Scalability for Emerging Technologies

As smart building ecosystems adopt Matter protocols and edge computing architectures, integrated platforms offer seamless expansion paths. Dedicated I/O pins accommodate sensor inputs for occupancy detection or ambient light harvesting, while reserved processing headroom supports Over-The-Air (OTA) firmware upgrades adding Zigbee mesh networking capabilities later. This modularity contrasts sharply with legacy systems requiring complete hardware overhauls to incorporate new functionalities—locking facilities into obsolete infrastructure just years after installation.

Environmental Stewardship Through Design

Sustainability extends beyond energy savings into material choices. Lead-free soldering and recyclable aluminum heatsinks align with circular economy principles. Some models even incorporate recovered rare earth elements from end-of-life motor magnets into their magnetic components. When paired with renewable energy sources like solar microinverters, these drivers achieve carbon footprints 78% lower than conventional counterparts according to LCA analyses conducted by third-party auditors. Such eco-credentials increasingly influence procurement decisions among ESG-conscious corporations.

Real-World Application Success Stories

From Broadway theater renovations using thousands of individually addressable fixtures controlled via single master panels to agricultural greenhouses optimizing photoperiodic schedules across hectares—the versatility shines through. One notable example involves retrofitting a historic hotel ballroom where noninvasive clip-on adapters preserved original chandelier aesthetics while upgrading to dimmable LED sources. Project managers praised the solution's ability to maintain architectural integrity without compromising modern functionality—a testament to thoughtful engineering balancing preservation with progress.

In heritage architecture prote

In heritage architecture prote

When small-batch customization

When small-batch customization

Have the electromagnetic emiss

Have the electromagnetic emiss

When Triac dimmable power supp

When Triac dimmable power supp