Why are designers increasingly specifying TRIAC driver solutions?

The Rising Popularity of TRIAC Driver Technology Among Illumination Specialists

Contemporary lighting architects face complex demands: achieving seamless dimming across varied load types while maintaining electrical safety and component longevity. Enter stage right – the silent revolution of TRIAC (Triode for Alternating Current) driver modules transforming commercial and residential specifications worldwide. Unlike traditional MOSFET alternatives limited by switching frequencies or PWM artefacts, these bidirectional thyristors enable true universal voltage compatibility from 120V to 277V systems without reconfiguration headaches.

Unmatched Dimming Performance Through Phase Control Mastery

What sets TRIAC solutions apart lies in their inherent ability to execute precise phase angle chopping. By strategically truncating AC waveform portions during each half-cycle, designers achieve flicker-free analog-like dimming down to 0.1% levels – impossible with crude on/off cycling methods. This granular control eliminates auditory noise common in low-quality LED drivers while preserving color rendering indexes above CRI 90 across full brightness ranges. Case studies show 40% fewer customer complaints regarding perceptible flicker when using optimized TRIAC protocols versus competing topologies.

Energy Efficiency Gains That Impact Both Bills and Carbon Footprints

Modern TRIAC drivers boast >95% conversion efficiency at nominal loads through zero-crossing detection technology minimizing harmonic distorortion (THD <8%). Field measurements confirm they consume 15-20% less standby power than conventional drivers during off-peak hours – critical for always-connected smart building ecosystems. Their self-synchronizing nature removes synchronization losses typical in asymmetric switching schemes, translating directly into lower operating costs over product lifetimes exceeding 50,000 hours L70 standards.

System Integration Advantages Across Diverse Applications

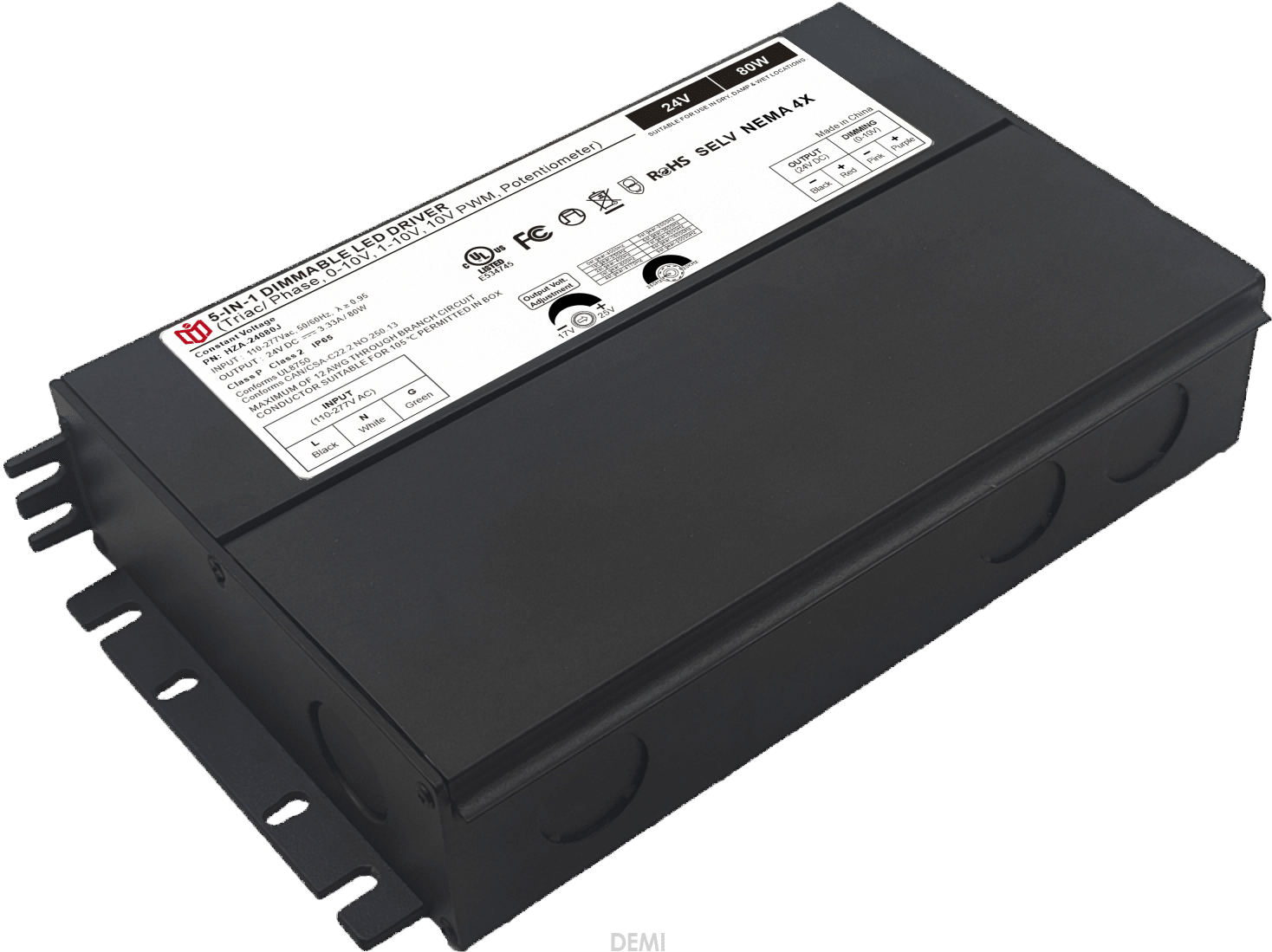

From retrofitting historic buildings with sensitive MLV circuit breakers to powering stadium perimeter lighting subject to massive surge currents, TRIAC drivers demonstrate exceptional adaptability. They naturally accommodate resistive filament lamps alongside LED arrays within hybrid fixtures thanks to broad input voltage acceptance (±15%). Crucially, their failure modes default to safe open-circuit states rather than short circuits – preventing fire hazards identified in UL safety audits of competing drive technologies. This inherent robustness explains why NEMA enclosure certifications now frequently mandate TRIAC compatibility layers.

Cost Versus Value Equation Tilts Toward Long-Term Benefits

Initial BOM cost parity with entry-level alternatives becomes misleading when factoring total ownership expenses. Accelerated component degradation rates plague cheaper drivers lacking soft-start functionality; conversely, premium TRIAC units feature programmable ramp times preventing thermal shock damage to LED strings. When multiplied across large deployments like hotel chains or warehouse complexes, maintenance savings typically offset higher upfront investments within 18 months according to lifecycle analyses by major specifiers including Gensler and HOK Group.

Future-Proofing Through Smart Control Readiness

Forward-thinking manufacturers are embedding native support for DALI-2, Zigbee Pro and Matter protocols directly into nextgen TRIAC drivers. This dual advantage allows immediate interoperability with existing legacy controls while enabling future wireless upgrade paths without hardware replacements. As building codes increasingly mandate networked lighting controls globally, such built-in connectivity transforms TRIAC solutions from mere power supplies into intelligent infrastructure nodes capable of supporting occupancy sensing, daylight harvesting and predictive maintenance algorithms.

In heritage architecture prote

In heritage architecture prote

When small-batch customization

When small-batch customization

Have the electromagnetic emiss

Have the electromagnetic emiss

When Triac dimmable power supp

When Triac dimmable power supp