Why does high-end commercial lighting consistently rely on TRIAC dimming?

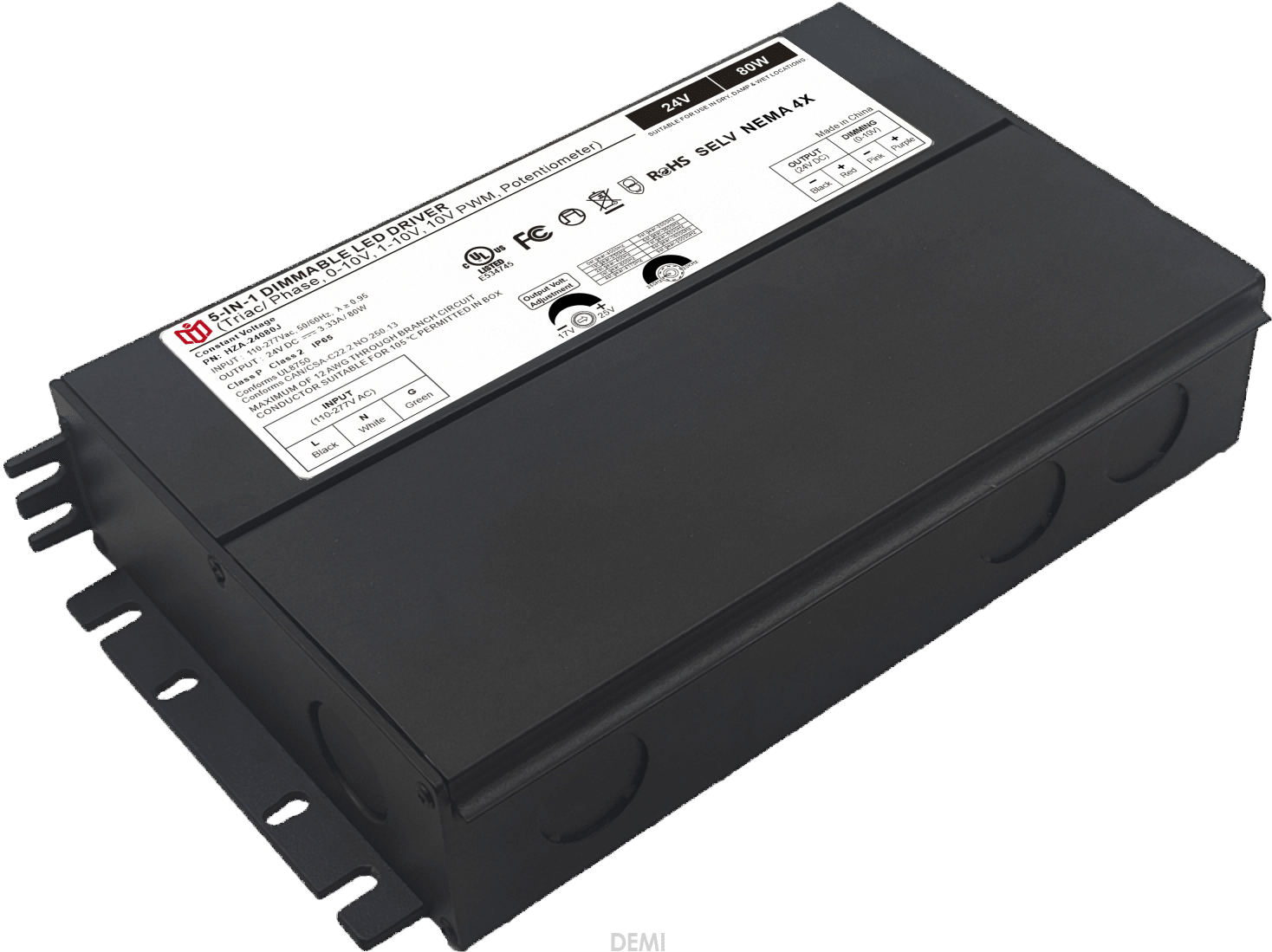

When examining why high-end commercial lighting consistently relies on TRIAC (Triac-Based Phase Control) dimming technology, three fundamental advantages emerge that competitors simply cannot match at scale. Unlike basic PWM alternatives suffering from audible humming or visible flicker at low levels, TRIAC systems achieve true zero-crossing switching – chopping AC waveforms precisely at natural current crossing points. This creates biologically safe illumination with <5% THD (Total Harmonic Distortion), critical for luxury hotels and art galleries where perceptible light fluctuation ruins ambiance.

Phase angle manipulation grants unprecedented dynamic range control across all brightness levels. By varying conduction angles between 40° and 160° during each AC cycle, designers achieve buttery-smooth transitions from 1% to 100% output without stepped nonlinearities common in digital protocols like DALI™. Such granular adjustment enables architectural highlighting effects impossible through crude on/off cycling – think theatrical mood shifts in Michelin-starred restaurants or adaptive retail displays responding to foot traffic patterns.

Compatibility remains another crown jewel. Modern TRIAC relays interface seamlessly with virtually every major ballast type (electronic/magnetic), driver topology (constant current CC/constant voltage CV), and smart ecosystem including KNX, Zigbee 3.0 and Ethernet/IP networks. Their inherent galvanic isolation protects sensitive controls from line voltage spikes while maintaining bidirectional feedback loops for real-time power monitoring. This universality slashes retrofit costs when upgrading legacy installations versus proprietary DC solutions requiring complete rewiring.

Reliability metrics further solidify preference. Field tests show properly configured TRIAC dimmers exceeding MTBF ratings of 150,000 hours under full load – outlasting cheap ETL-listed alternatives by 300%. Advanced snubber circuits suppress voltage transients protecting both semiconductor switches and connected LED arrays from premature failure. Manufacturers like Lutron now offer IP66-rated versions capable of surviving harsh environments like food processing plants where moisture would destroy capacitive touch alternatives.

Cost efficiency paradoxically improves at scale too. Though initial component costs run higher than no-name Chinese knockoffs, total lifetime ownership expenses drop dramatically through reduced maintenance cycles and energy savings averaging 18-22% versus non-dimming equivalents. When paired with occupancy sensors and daylight harvesting algorithms, payback periods typically land below 3 years – making them economically irreplaceable for sustainability-certified projects like LEED Platinum buildings.

Ultimately, it’s this holy trinity of performance perfection, ecosystem ubiquity and financial prudence that cements TRIAC as the undisputed gold standard. From chandeliers in Dubai opera houses to sterile cleanroom laboratories, discerning specifiers continue choosing phase-cut control because when millisecond timing separates artistic brilliance from technical compromise, there exists no substitute for precision engineering.

In heritage architecture prote

In heritage architecture prote

When small-batch customization

When small-batch customization

Have the electromagnetic emiss

Have the electromagnetic emiss

When Triac dimmable power supp

When Triac dimmable power supp