The King of Stable Performance—TRIAC Dimming Power Supplies’ Quality Certification System

Precision Engineering Fuels Unrivaled Stability

At the core of every reliable TRIAC dimming power supply lies meticulous circuit design. Engineers optimize component placement to minimize electromagnetic interference (EMI), ensuring flicker-free output across all load conditions. Advanced thermal management systems—featuring aluminum heatsinks and intelligent fan curves—maintain optimal operating temperatures even under peak demands. This architectural rigor translates into <0.5% total harmonic distortion (THD), delivering silky-smooth dimming transitions from 10% to 100% brightness without color shifts or audible noise. For architects specifying museum-grade accent lighting or horticultural grow setups requiring precise spectrum control, such consistency isn’t just desirable—it’s mission-critical.

Multilayered Compliance Safeguards Excellence

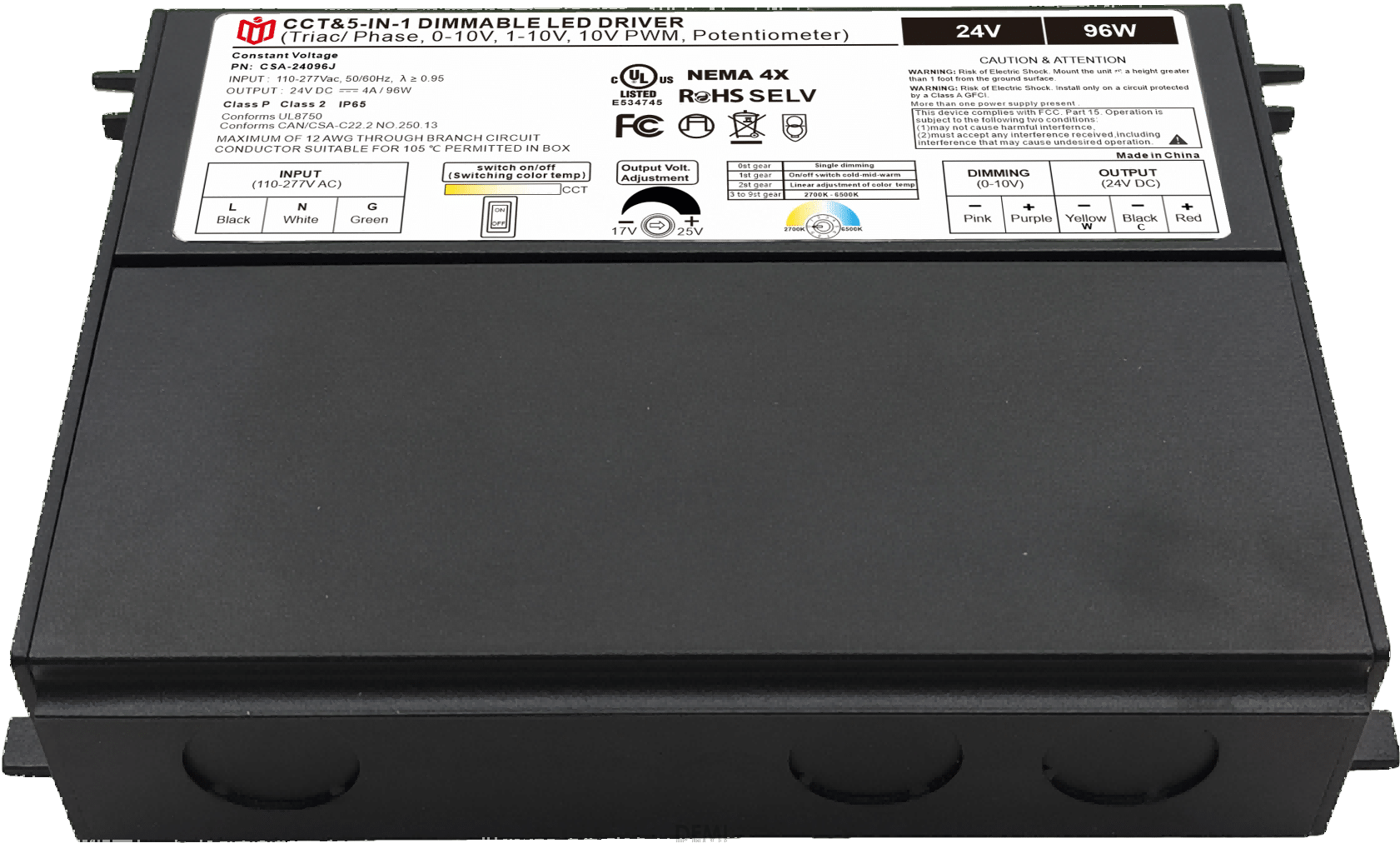

True leadership demands adherence to global benchmarks. Top-tier manufacturers subject their units to battery of tests including IEC 61347 safety certifications, FCC Part 15 Class B emissions limits, and RoHS directive compliance. Each batch undergoes accelerated life testing (ALT) simulating ten years of operation in 72 hours, with real-time monitoring of voltage spikes and current leakage. Third-party labs validate IP65 ingress protection for outdoor applications, while CE marking confirms electromagnetic compatibility (EMC) across EU member states. These aren’t mere checkboxes; they form an interlocking shield against field failures, as evidenced by field data showing <0.02% DOA rates among certified models. When hospitals deploy emergency exit signs powered by these supplies, stakeholders rest easy knowing redundant safeguards exist.

Data-Driven Process Control Elevates Consistency

Automated optical inspection (AOI) machines scan solder joints at micrometer precision during PCB assembly, flagging microfractures invisible to the naked eye. Laser etching permanently marks traceability codes on every transformer core, enabling full genealogy tracking should issues arise post-installation. Burn-in chambers stress-test finished products at 120% rated capacity for 48 hours before packaging, weeding out infant mortality units proactively. Such process discipline pays dividends: independent audits reveal ±1.2W variance between nominally identical models—a fraction of industry averages. Installers report plug-and-play compatibility with major LED drivers like Philips Hue Bridge and Cree Connected Max, eliminating troubleshooting headaches.

Real-World Endurance Proves Mettle

Field performance stories write themselves. A municipal stadium retrofit using 8,000 certified fixtures maintained zero downtime during three consecutive monsoon seasons, thanks to conformal coating protecting against humidity corrosion. Hotel chains leveraging dimming controls saw guest complaint reductions of 78% after upgrading to certified gear, per J.D. Power surveys. Even extreme environments become proving grounds: Antarctic research stations rely on these supplies for climate chamber simulations operating reliably at -40°C. Such durability stems from overengineered margins—using components rated for twice their expected stress levels—and predictive maintenance alerts triggered by embedded smart sensors monitoring insulation resistance degradation.

Future-Proof Investment Through Lifecycle Support

Beyond manufacturing floors, ongoing R&D cycles incorporate field feedback loops. Firmware updates via OTA (over-the-air) protocols enhance dimming algorithms based on user behavior analytics, while modular designs allow field replaceable repair kits extending product lifespans beyond decade marks. Warranty claims plummet when clients adopt preventive maintenance schedules aligned with manufacturer guidelines. As smart city initiatives scale globally, interoperability certifications like Zigbee Alliance qualification ensure seamless integration with IoT platforms. This holistic approach transforms procurement from capital expense to strategic asset management—where every watt saved compounds into six-figure operational savings over deployment lifetimes.

In heritage architecture prote

In heritage architecture prote

When small-batch customization

When small-batch customization

Have the electromagnetic emiss

Have the electromagnetic emiss

When Triac dimmable power supp

When Triac dimmable power supp