How were the quality standards for LED dimming power supplies established?

Foundational Needs Driving Standardization

When early adopters began integrating dimmable LED fixtures into architectural projects during the 2000s, wildly inconsistent performance exposed critical gaps. Installers reported flickering issues at low brightness levels while electricians struggled with compatibility across different driver models. This chaos prompted industry coalitions like Zhaga Consortium to convene technical working groups focused on harmonizing electrical parameters—particularly addressing the delicate balance between pulse-width modulation frequencies and human perceptual thresholds. Their initial whitepaper established baseline requirements for smooth dimming curves spanning 0.1%–100% output range without color shift or audible noise.

Safety Imperatives Shaping Protocol Design

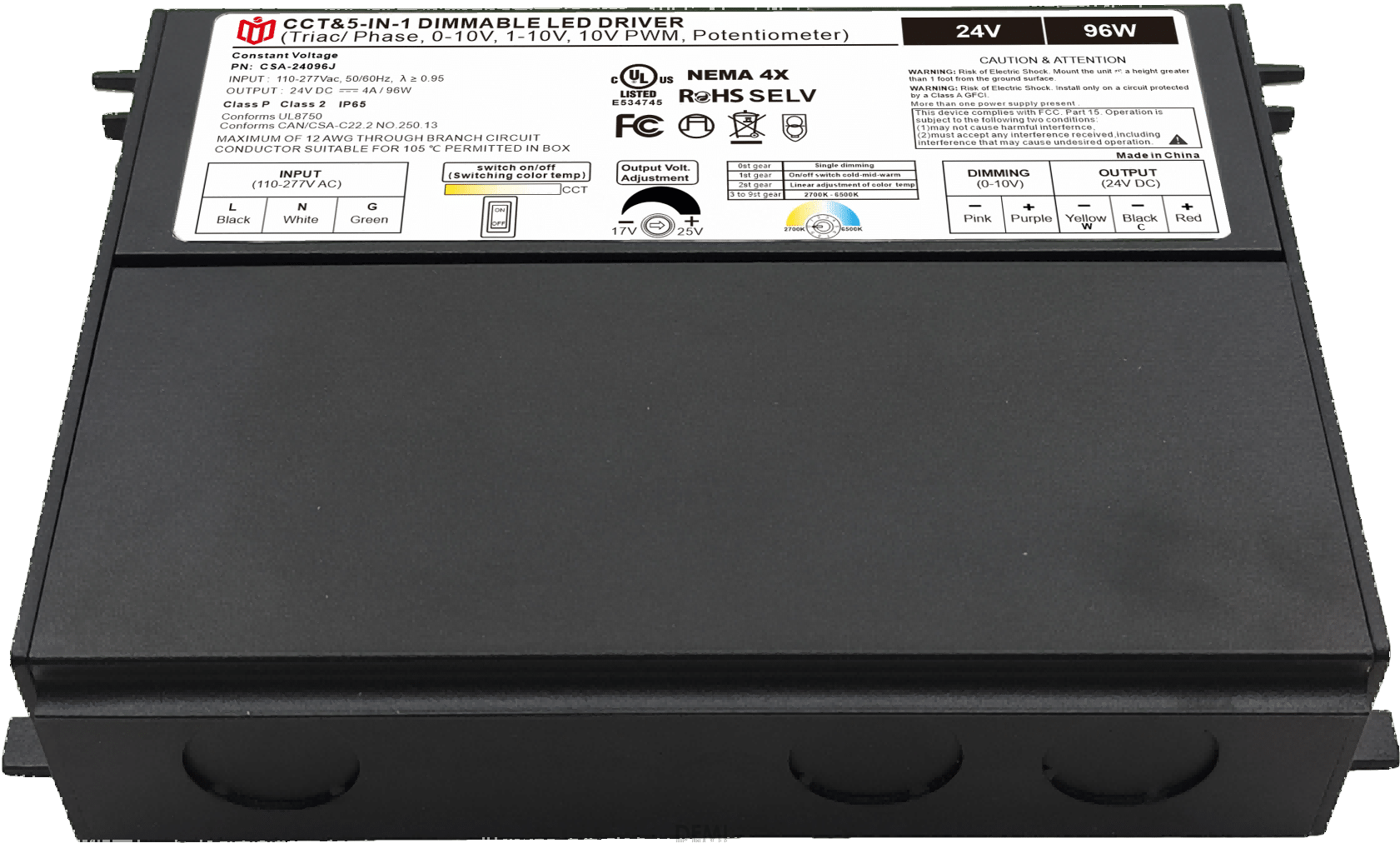

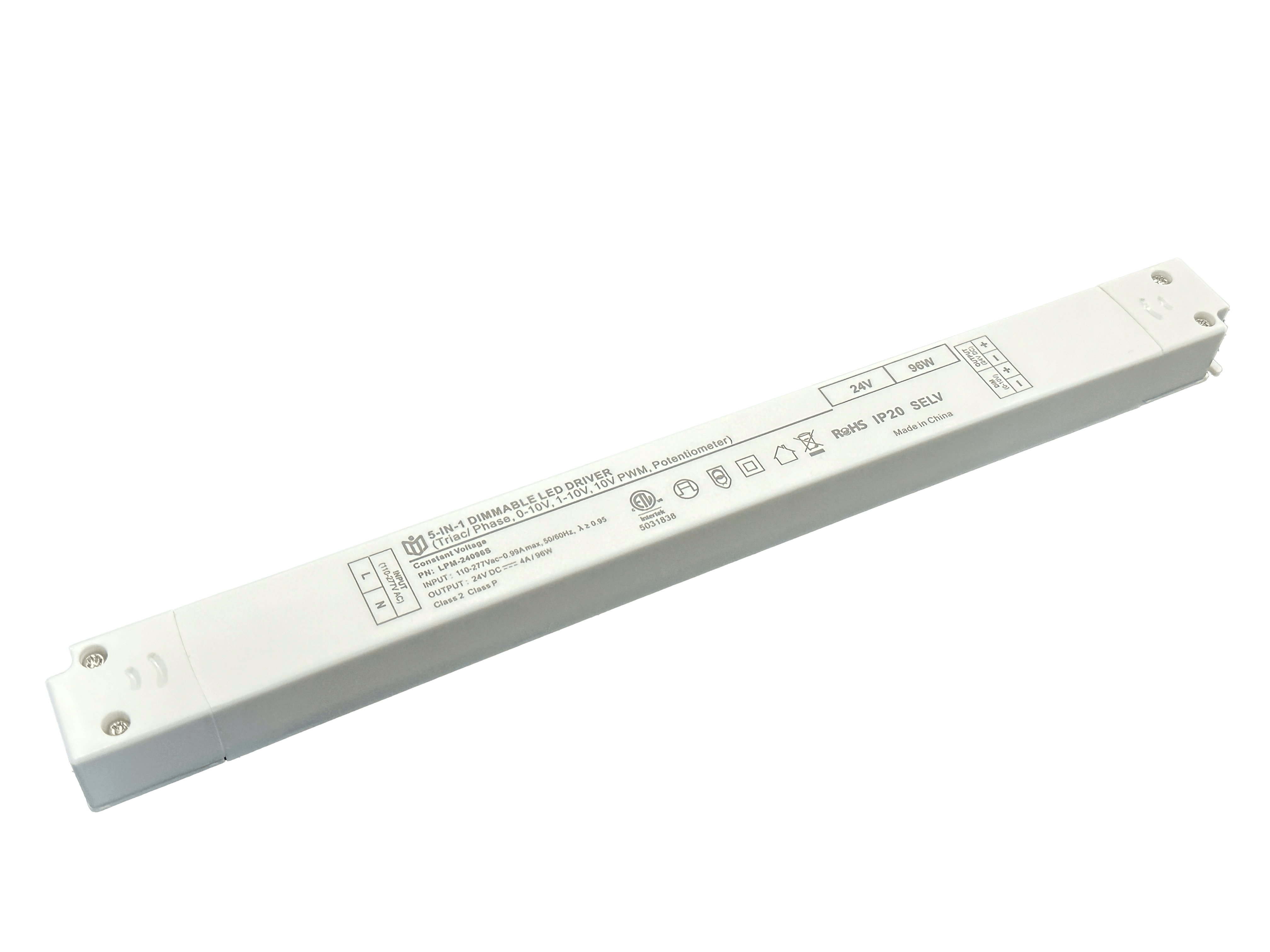

Regulatory bodies quickly recognized fire hazards inherent in substandard components handling variable loads. Underwriters Laboratories (UL) introduced specialized listing categories demanding double-insulated enclosures rated IP67+ for moisture resistance, alongside mandatory overcurrent protection circuitry tested under fault conditions simulating short circuits. Simultaneously, IEC TC34 working committee revised harmonized standards to mandate electromagnetic interference suppression compliant with CISPR Class B limits—a non-negotiable requirement for residential deployments near sensitive electronics. These safety mandates forced manufacturers to adopt reinforced isolation barriers between high/low voltage sections using certified materials like LCP thermoplastics.

Performance Benchmarking Methodologies

Third-party labs developed repeatable test protocols involving programmable electronic loads simulating real-world scenarios: sudden step changes from full glow to nightlight modes, sustained operation at extreme ambient temperatures (-40°C to +85°C), and accelerated life cycling exceeding 50,000 switches. Key metrics included rise/fall times measured in microseconds, total harmonic distortion below THD<8%, and power factor correction maintaining >0.95 across all load points. Notably, Energy Star program added efficiency tiers rewarding units achieving >90% conversion rates while maintaining <0.5W no-load consumption—pushing gallium nitride semiconductor adoption for reduced switching losses.

Global Interoperability Initiatives

Cross-border trade acceleration required transcending regional certification silos. The International Commission on Illumination (CIE) published SLL Series technical reports defining universal communication protocols like DALI-2 supporting bidirectional feedback between controllers and drivers. Parallel efforts by ENERGY STAR® created unified labeling systems categorizing products by dimming resolution (8-bit vs 16-bit depth), enabling facility managers to specify compatible ecosystems regardless of manufacturer origin. Today's multi-vendor systems owe their plug-and-play capability to these open architecture frameworks standardized through ANSI/ASHRAE guidelines.

Ongoing Iteration Through Field Data

Post-market surveillance reveals emerging failure modes rarely captured in controlled environments. Field reports from museum curators managing priceless artwork under low-level illumination identified long-term drift issues requiring autocalibration features now mandated in museum-grade specifications. Similarly, horticultural lighting applications drove updates allowing precise spectrum tuning without disrupting photoperiod cycles—leading to IEC TR 62778 supplements covering dynamic light recipes. Modern quality assurance combines Finite Element Analysis stress modeling with AI-driven predictive maintenance algorithms monitoring capacitor degradation patterns across fleets of deployed units.

Future-Proofing Through Modular Compliance Pathways

As smart city initiatives scale up, new challenge areas emerge around cybersecurity vulnerabilities in networked lighting controls. Emerging standards like CSA C817 incorporate firmware signing requirements and secure boot processes while maintaining backward compatibility with legacy installations through adapter modules. Manufacturers now design products anticipating circular economy principles—using standardized connector footprints enabling field replacement of aging power stages rather than discarding entire luminaires. This evolutionary approach ensures tomorrow's sustainability goals don't compromise yesterday's hard-won reliability achievements.

In heritage architecture prote

In heritage architecture prote

When small-batch customization

When small-batch customization

Have the electromagnetic emiss

Have the electromagnetic emiss

When Triac dimmable power supp

When Triac dimmable power supp