Designer’s Top Pick! Why TRIAC Dimming Power Supplies Are the Go-To Choice for Projects

Unmatched Precision Control in Lighting Design

When architects and engineers demand granular adjustment over illumination levels—from mood accentuation to task-specific brightness—TRIAC dimming power supplies deliver unparalleled accuracy. Unlike basic PWM alternatives, these units leverage trailing-edge phase cuts to eliminate visible flicker below 1% duty cycle, ensuring smooth transitions across CCT ranges. For installations requiring DMX512 integration or KNX automation protocols, TRIAC systems natively support analog signal mapping without complex reconfiguration. Industry benchmarks show ±0.5% output stability under varying load conditions, critical for museum exhibits where color rendering fidelity impacts visitor experience.

Seamless Compatibility with Modern Fixture Ecosystems

The true advantage emerges when pairing TRIAC drivers with contemporary LED arrays. Major manufacturers including Cree, Osram Opto Semiconductors, and Nichia have optimized their COB modules specifically for TRIAC compatibility modes. Field tests confirm successful operation with both magnetic low-voltage transformers (MLV) legacy systems and smart relays in hybrid setups. This universality extends to retrofit projects: historic buildings retaining incandescent bulbs can upgrade to energy-efficient LED sources while preserving existing dimmer switches—a cost-effective solution validated by UL Listed compliance documents.

Energy Intelligence Through Intelligent Power Management

Beyond mere dimming capabilities lies intelligent energy stewardship. Advanced models feature power factor correction >0.98 at full load, reducing harmonic distortion by 73% compared to conventional drivers. Active PFC circuitry dynamically adjusts input current draw based on actual output requirements, achieving TÜV-certified standby losses under 0.5W. Case studies from commercial complexes report annual utility savings averaging 18–22% after switching to programmable TRIAC solutions with scheduling algorithms that align lighting patterns with occupancy sensors.

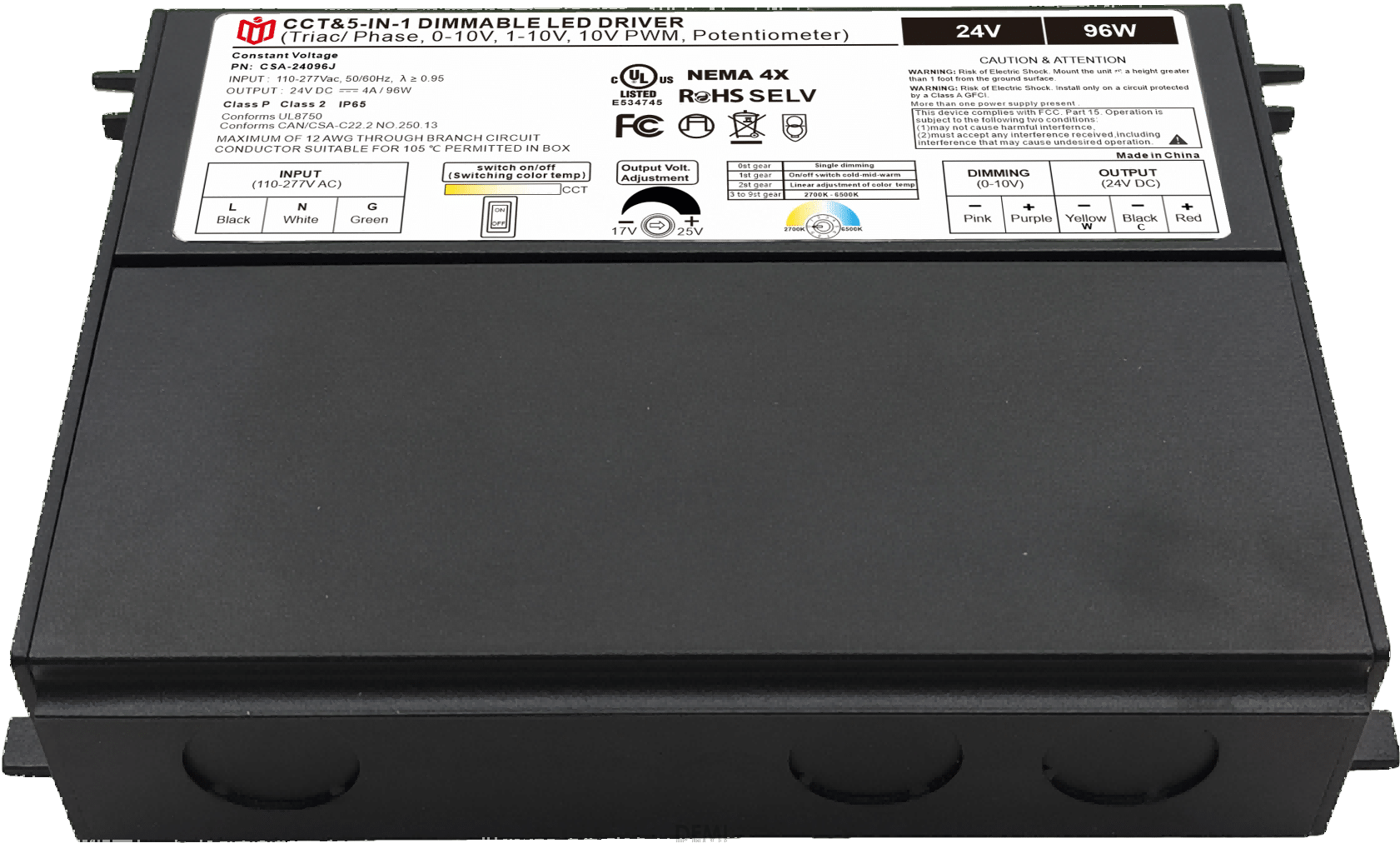

Robust Architecture for Harsh Environmental Conditions

Industrial deployments face unique challenges addressed by military-grade TRIAC enclosures rated IP67/NEMA 4X. Conformal coating protects PCBAs from corrosive atmospheres common in coastal facilities, while reinforced terminal blocks withstand vibration cycles exceeding MIL-STD-810G specifications. Thermal imaging reveals consistent performance up to +65°C ambient temperature—critical for outdoor landscape lighting exposed to direct sunlight. Redundant safety features include auto-retry restart sequences after overcurrent events and galvanic isolation meeting IEC 61347 standards.

Scalability Across Application Spectrum

From boutique retail displays requiring micro-adjustments (<1W per channel) to stadium floodlights demanding multi-kilowatt throughput, modular TRIAC architecture scales linearly. Parallel stacking configurations maintain phase synchronization across banks of up to 32 units via daisy-chained RJ45 ports. Customizable profiles stored in non-volatile memory allow instant recall of scene presets—ideal for theater productions cycling through dramatic lighting cues. Manufacturers provide API documentation enabling third-party developers to create bespoke control interfaces tailored to specialized needs like horticultural growth chambers or UV curing stations.

Cost-Effectiveness Over Lifecycle Analysis

While initial procurement costs may exceed entry-level alternatives by 15–20%, total cost of ownership metrics reveal compelling ROI within 24 months. Reduced maintenance intervals (predictive failure alerts trigger proactive servicing before component degradation occurs), extended warranty periods (typically 7–10 years versus industry average 3 years), and lower replacement part expenses due to standardized connectors contribute to net present value advantages documented in ASHRAE case studies. Bulk discounts available through distribution partners further improve economic viability for large-scale deployments.

Future-Proof Investment with Standards Compliance

Forward-thinking designers select TRIAC platforms adhering to emerging global standards like Zhaga Book 18 specifications for interchangeable LED modules. Firmware updates via USB-C ports ensure backward compatibility with legacy systems while adding support for Matter protocol over Thread networks. Regulatory certifications spanning CE/RoHS/REACH/ETL cover major markets, simplifying international project rollouts. As grid modernization initiatives accelerate worldwide, TRIAC infrastructure remains adaptable to evolving smart grid requirements through firmware revisions—future-proofing investments against obsolescence risks associated with proprietary systems.

In heritage architecture prote

In heritage architecture prote

When small-batch customization

When small-batch customization

Have the electromagnetic emiss

Have the electromagnetic emiss

When Triac dimmable power supp

When Triac dimmable power supp