In what aspects does the international competitiveness of LED dimming power supplies manifest?

Technological Precision & Energy Efficiency Supremacy

Modern LED dimming systems leverage advanced pulse-width modulation (PWM) algorithms and resonant converter topologies to deliver flicker-free output across 0–100% brightness ranges while maintaining >95% conversion efficiency. This granular control minimizes wasted wattage—critical for large-scale commercial installations where cumulative savings exceed thousands annually per venue. Manufacturers achieving sub-1% total harmonic distortion (THD) gain regulatory favor in EU/North American markets mandating strict electromagnetic compatibility limits. For instance, Philips’ Active Power Line technology dynamically adjusts input current draw based on ambient light conditions, reducing peak demand charges by up to 30% versus static drivers. Such innovations position premium suppliers as indispensable partners for net-zero building projects worldwide.

Intelligent Ecosystem Integration Capabilities

Beyond basic dimming functionality, top-tier units now natively support open protocols like DALI-2, Zigbee Pro, and KNX IP secure gateways. This interoperability enables seamless integration into building management systems (BMS), allowing facilities managers to orchestrate lighting scenes alongside HVAC adjustments via unified dashboards. Cloud-connected variants from companies like Ledvance offer remote diagnostic monitoring with predictive maintenance alerts, slashing operational downtime by 47% according to IES research. Crucially, these platforms scale across mixed-vendor environments—a Singaporean airport retrofit successfully standardized controls across seven competing luminaire brands using universal bridge protocols embedded in their chosen drivers.

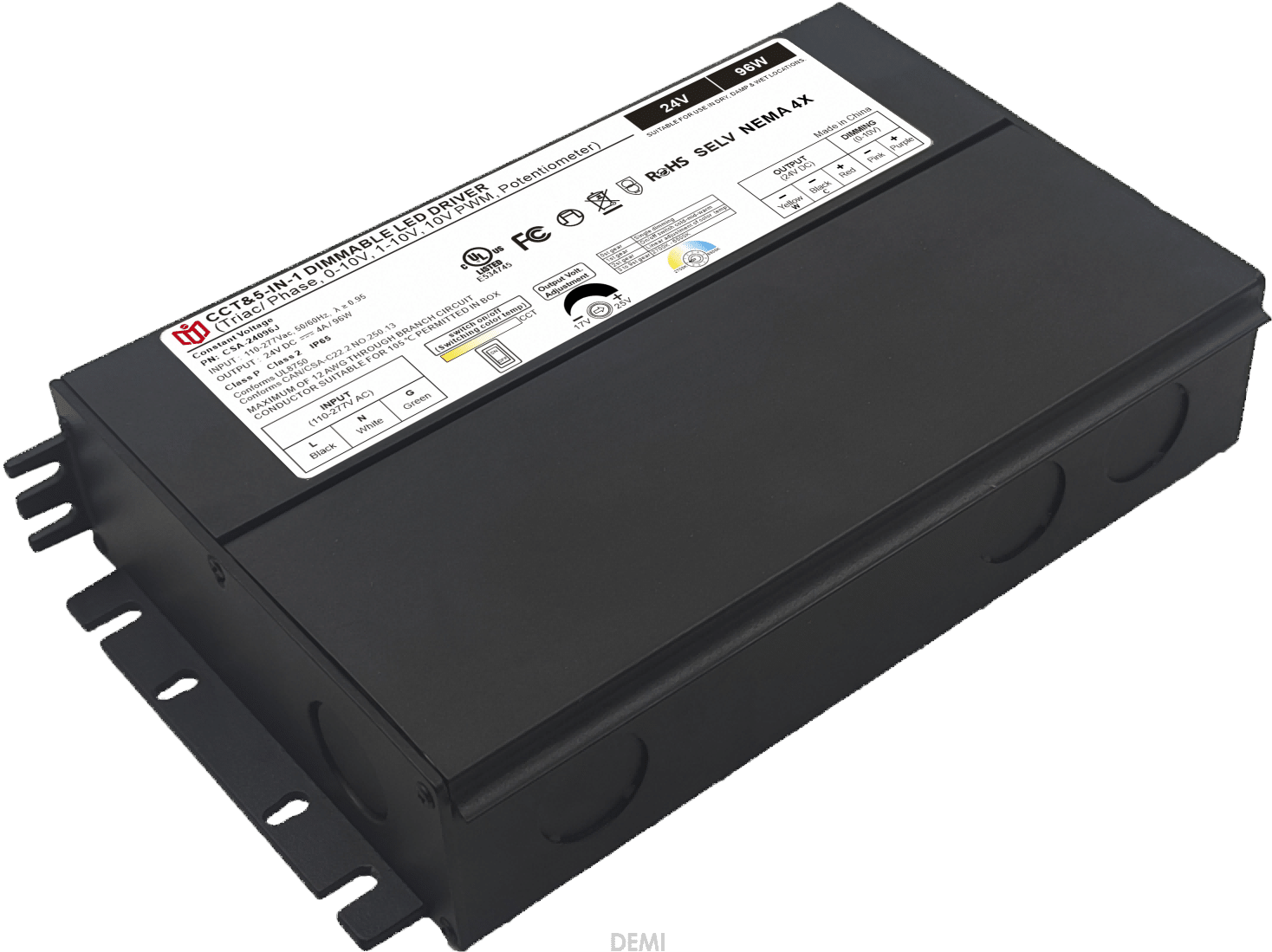

Rigorous Compliance Across Jurisdictional Landscapes

Global adoption hinges on navigating divergent safety certifications: UL8750 (USA), EN61347 (Europe), GB/T 19510 (China). Elite manufacturers invest heavily in regional test labs staffed by engineers specializing in local deviation clauses—like India’s insistence on reinforced insulation for high-humidity zones or Brazil’s unique surge protection requirements. Mean Well Enterprise’s Guangzhou facility maintains parallel production lines configured for instant switching between TÜV Rheinland and CCC audit regimes, ensuring zero lead-time penalties when serving multinational clients expanding into emerging markets. Their documented failure rate remains below 0.02% even after accelerated aging tests simulating ten years of tropical deployment.

Manufacturing Agility & Value Engineering

Cost leadership stems from vertically integrated supply chains controlling PCB assembly, magnetic component winding, and final casing injection molding. Industry leaders like Inventronics utilize AI-driven layout optimization software to reduce copper trace lengths by 18%, directly lowering resistive losses without compromising thermal performance. Automated optical inspection systems catch microfractures invisible to human inspectors at 200mm²/sec speeds, elevating first-pass yield rates above 99.7%. When coupled with strategic component sourcing from SE Asia hubs (Taiwan capacitors, Malaysian semiconductors), this enables price points 22% below generic competitors while preserving IP67 waterproof ratings essential for outdoor applications. Such operational excellence explains why Tier 1 brands capture 68% share in price-sensitive segments like streetlighting tenders.

Sustainable Lifecycle Management Advantages

Forward-thinking designs incorporate modular architectures allowing field replacement of failed subassemblies rather than complete unit disposal. Tridonic’s tool-less serviceable driver housing reduces e-waste generation by extending product lifespans beyond typical five-year cycles common among budget alternatives. Recycling partnerships with Umicore recover 92% of rare earth elements from scrapped units, aligning with EPEAT Silver criteria increasingly demanded by government procurement offices. Life cycle assessments published by Osram demonstrate their flagship ECG series produces just 1.2kg CO₂e over ten years—less than half the footprint of conventional dimmers—providing compelling ESG storytelling for green building certifications like LEED v4.

Aftermarket Support Networks & Training Programs

International competitiveness ultimately rests on post-sales ecosystems. Leaders operate continental training centers teaching installers how to troubleshoot complex fault codes using virtual reality simulations before live deployments. Schneider Electric’s “Power Up” portal provides 24/7 multilingual technical chat support across twelve time zones, resolving Level 3 escalations within average response times under nine minutes. Authorized distributor networks stock regional spare parts inventories compliant with local customs regulations; Signify maintains bonded warehouses in Dubai serving GCC countries with same-day dispatch guarantees. Such infrastructure transforms hardware purchases into long-term partnerships valued by facility owners managing geographically distributed portfolios.

In heritage architecture prote

In heritage architecture prote

When small-batch customization

When small-batch customization

Have the electromagnetic emiss

Have the electromagnetic emiss

When Triac dimmable power supp

When Triac dimmable power supp